CNC machine tool service: efficiency and practical solutions from Assistec

Assistec is your partner with over 25 years of experience in full service for CNC machine tools, offering both electronic and mechanical technical support. Our main objective is to minimise machine downtime, ensuring a rapid return to production and an efficient return on investment.

CNC electronic support services: rapid diagnosis and effective solutions

Our electronic service on CNC machine tools is characterised by a comprehensive service that begins with a careful preventive telephone diagnosis by our service department. This initial phase is crucial to quickly understand the nature of the problem. Thanks to our well-stocked electronic spare parts warehouse, we are often able to resolve the fault already during the first technical intervention.

Specialised work on Fanuc and Mitsubishi electronics

We specialise in servicing machine tools equipped with Fanuc and Mitsubishi electronics, two of the world's leading manufacturers. Our technicians have the experience and expertise to work on machines from European and Asian manufacturers using these reliable technologies.

A practical example? Imagine that a Fanuc-controlled machining centre starts showing communication errors with the axis drives. Our telephone diagnosis could direct the technician to check specific wiring or parameters. If the problem lies in a faulty drive, the immediate availability of the spare part in our warehouse would allow for a quick replacement, drastically reducing downtime.

Service on CNC drives and motors: repair and replacement

We provide qualified service on axis and spindle drives, as well as motors of any series mounted on CNC machine tools. Our in-house workshop is equipped to repair servo drives, as in the recent case of a Fanuc robot restored to full operational efficiency through a meticulous process of

- disassembly

- inspection

- repair

- testing

We also offer the possibility of retrofitting (an opportunity to technologically upgrade lathes and machining centres, replacing the entire electronic, electrical and measuring systems, and integrating new control and automation systems), replacing Pro-Motion or Vision drives/motors with the most modern and high-performance Fanuc-branded handling systems, with tangible benefits in terms of reliability and reduced downtime.

When might you need us? Consider a CNC lathe whose spindle begins to vibrate abnormally and produce out-of-tolerance parts. Analysis might reveal a problem with the spindle drive. Our technicians can repair the drive in our workshop, avoiding costly full replacements and ensuring that the machine's functionality is restored quickly.

PLC logic modifications and safety

We carry out modifications to the PLC (Programmable Logic Controller) logic of the machines to ensure the safety of the installations in accordance with current regulations.

This includes the implementation of systems such as automatic doors and conveyor belts, as well as increasing M-codes for the machine operator, such as in the case of rigid tapping.

We also carry out specific inspections to assess and implement the necessary measures to secure obsolete machine tools.

Think of an old CNC milling machine that needs to be adapted to new safety regulations. Our technicians can intervene on the PLC logic to implement light curtains, safety interlocks and operating sequences that guarantee the protection of operators during machine operation.

CNC Mechanical Support Services: timely intervention and lasting solutions

Our mechanical service on multi-brand machine tools is designed to offer a complete all-round service, with experienced technicians able to intervene quickly to solve any mechanical problems that may arise.

Ordinary and extraordinary maintenance

We perform routine and extraordinary maintenance on multi-brand machine tools, which is essential to preserve efficiency and prevent sudden breakdowns.

A routine maintenance plan for a machining centre might include checking and lubricating guides, checking tool wear, and general cleaning of the machine. In the event of a sudden failure, such as a broken spindle bearing, our extraordinary maintenance service would intervene quickly to replace the damaged component and restore full machine functionality.

Spindle and electro-spindle overhaul

We undertake the overhaul of spindles and electro-spindles in our fully equipped machine shop.

Our interventions include

- thorough disassembly

- detailed inspection

- replacement of worn bearings

- meticulous cleaning

- reassembly with final inspection

We have successfully completed overhauls on spindle assemblies with tolerance problems due to bearing wear, and on Omlat electro-spindles installed on Famup machines, solving tool locking problems. Even in the case of bearing failures with spindle blockage or motor spindles with noisy bearings and broken shafts, our technicians intervene with precision to restore full efficiency.

For example: if the spindle of a CNC milling machine starts making abnormal noises and exhibiting concentricity problems, an overhaul of the spindle at our workshop would identify and replace the damaged bearings, rectify the spindle taper if necessary, and restore the precision and reliability of the entire system.

Geometrical checks and dynamic tests: performance verification

We perform geometric checks and dynamic tests using advanced instrumentation such as vibrometers, accelerometers and load cells to verify the performance and accuracy of machine tools. These checks are essential to ensure that machines operate within required tolerances and maintain high quality standards in production.

Repair and replacement of mechanical components

Our mechanical services include the replacement of guides and slides, grinding of the spindle cone directly on the machine, maintenance and replacement of the coolant refrigerator (chiller), the application of safety guards, and the overhaul or replacement of telescopic casings. We also have experience in restoring lathe turrets with mechanical blockage problems, which are solved by replacing bearings and seals and testing for oil leaks.

Mechanical preventive maintenance

We offer mechanical preventive maintenance services that allow customers to schedule downtime according to production needs.

The goal is to minimise the number of unplanned interventions during the year and have a more predictable and consistent maintenance budget. Our standard mechanical service contracts include discounted hour packages, extra service hours and a priority telephone help desk, covering activities such as checking for oil leaks, filter wear, chip conveyor condition and cooling system efficiency.

Unlike the aforementioned routine maintenance plan, here we are talking about a more comprehensive strategy that can also include more in-depth interventions, based on predictive analysis or time schedules, to avoid future breakdowns.

This makes it possible to detect leaks or malfunctions in the control unit of a CNC milling machine at an early stage, for example, avoiding major damage and costly unexpected downtime.

Automation and Monitoring: Towards a New Industry Model

The quality of Assistec services is also tangible in our partnerships.

A concrete example is the collaboration with an experienced company like RIKI . This synergy was created with the aim of providing companies with a complete solution: a machine tool equipped with a robot cell.

In today's environment, many companies find it difficult to find qualified personnel. Industrial automation is an effective answer to this problem, offering advantages in terms of productivity, efficiency and long-term savings.

Thanks to this collaboration, we can offer the market a technologically advanced solution that is advantageous in several respects.

The machine presented at MECSPE 2025 is a Hyundai WIA model SE-2200LM CNC lathe, equipped with a FANUC 0i-MF PLUS CNC control. This combination ensures high performance and seamless integration with our stocker, creating a highly efficient and high-performance automated machining system.

For more information about our electronic and mechanical support services for CNC machine tools, please do not hesitate to contact us at 0522-989436 or by email at vendite@assistec.cc .

We are here to offer you technology and support, with the aim of building a future of excellence for your business.

Recent Posts

-

MAPPS Mori Seiki: cutting-edge technology at the service of CNC programming

In the world of CNC machining, Mori Seiki has always been synonymous with precision, efficiency and innovation. Among the systems that have contributed most to building this reputation, MAPPS (Machine Advanced Programming Production System) occupies a place of absolute importance. This hardware, integrated into Mori Seiki machines (updated in CELOS), allows for intelligent management of every stage of production, from programming to simulation. Today, thanks to the many years of experience of the Assistec laboratory, it is possible to repair MAPPS Mori Seiki, with the certainty of turning to a team of qualified, up-to-date and responsive professionals.

-

CNC lathes are the beating heart of many mechanical workshops and manufacturing companies. However, their ability to guarantee precision, production continuity and impeccable finishes depends on a factor that is often underestimated: maintenance. Regular mechanical and electronic maintenance is not only a technical requirement, but also a business strategy that reduces machine downtime, preserves product quality and extends the life of the equipment. This guide explores all the operations necessary for comprehensive maintenance, with practical advice and guidance on when it is essential to rely on specialised professionals.

-

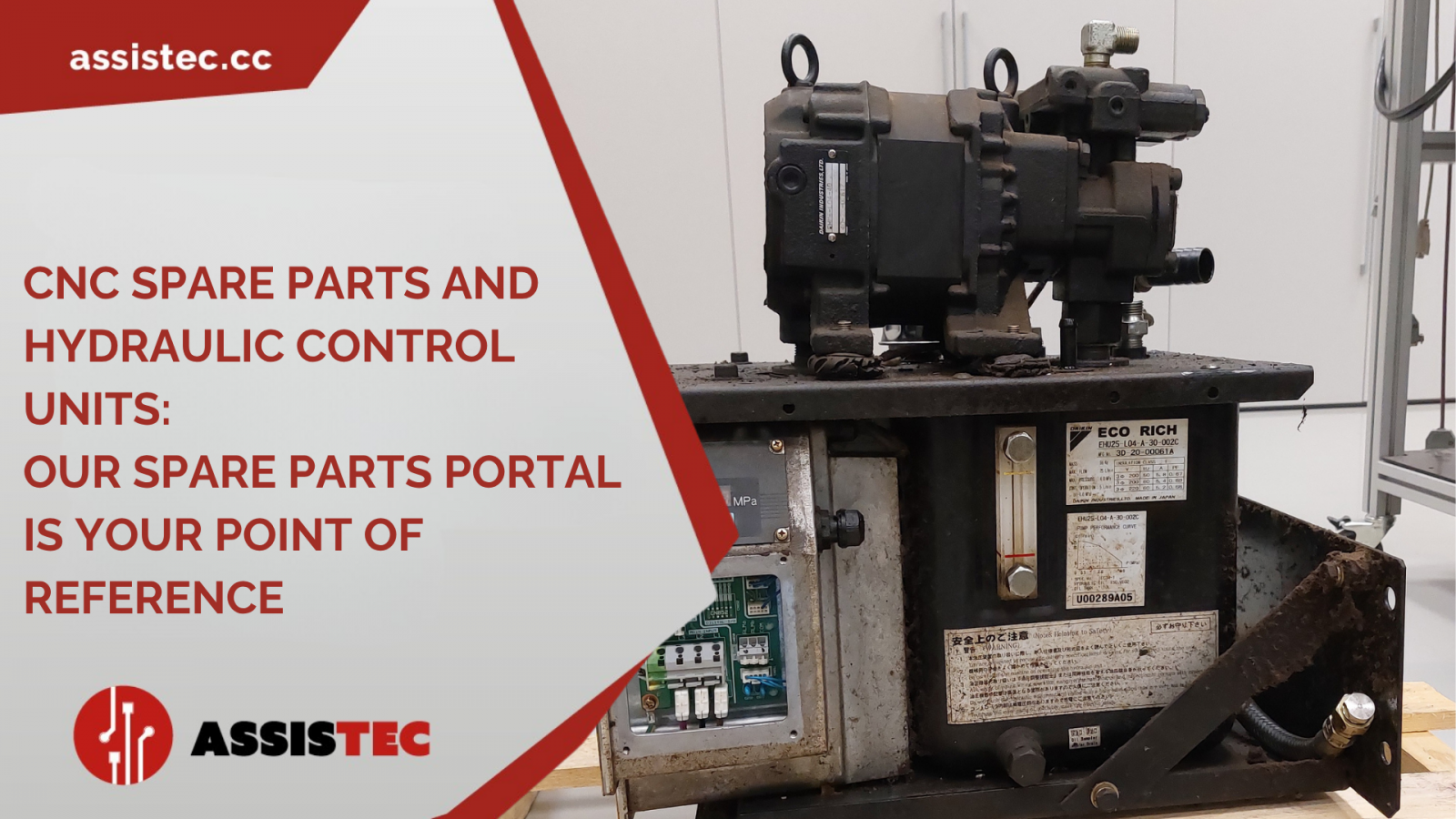

The efficient management of CNC machine tools cannot be separated from a reliable, timely and well-organised spare parts system. This is where the Assistec Spare Parts Portal comes into play, designed to provide concrete support to workshops, maintenance technicians, technical managers and industrial buyers.

Thanks to direct integration with the automated warehouse, the portal allows you to identify and order new and remanufactured components in just a few clicks, with real availability and fast shipping.

Among the most requested spare parts today are hydraulic control units, which are essential for ensuring the operational continuity of CNC systems