Machine tool maintenance: how to extend the life of numerically controlled machines

The importance of preventive maintenance for CNC machine tools

Just like any other equipment within a company, it is crucial to check the health of machine tools. Failure to do so can result in very serious risks, including decreased productivity, machine downtime and even unexpected repair expenses. This is why, in recent years, many manufacturers have embraced a philosophy of prevention by conducting regular and rigorous checks on CNCs and replacing mechanical and electrical components subject to wear and tear. Otherwise, meeting the standards demanded of a modern smart factory operating within an Industry 4.0 supply chain would be impossible.

Advanced monitoring and diagnosis: how to prevent unforeseen breakdowns

Before maintenance, however, there is monitoring. Companies can use highly sophisticated software that enables the real-time monitoring of all their machining centres, conducting diagnostics, even remotely. This ensures continuous data transmission and collection from the machines so that any production anomalies can be detected and corrected well in advance and in the shortest time possible. This technological integration enables continuous monitoring of crucial aspects of CNCs, such as temperature, vibrations and performance, and ensures uninterrupted operations.

Preventive, corrective or predictive maintenance of CNC machine tools

How does CNC maintenance work? First of all, a distinction must be made. Even today, many people believe that maintenance solely entails repairs or replacements, but this is not the case. A check-up is not merely a corrective action, but also and, above all, a regularly scheduled intervention that verifies whether the parts of a machine are intact and working properly. With this in mind, any parts that have lost effectiveness over time are replaced as a preventive measure to prevent breakdowns and disruptions in production. More specifically, ordinary (or periodic) maintenance entails scheduling an appointment to optimise machine performance and pre-emptively address potential wear and tear issues. Extraordinary maintenance, on the other hand, focuses on rectifying a specific fault that has just occurred in order to resume production.

Personnel training

Effective machine tool maintenance necessitates more than just the use of state-of-the-art software; a team of highly specialised technicians capable of immediate intervention is also necessary. This is why most mechanical and electronic service partners are allocating more and more time and resources to train personnel. The aim is to create a business unit with in-depth and extensive expertise in machine tools.

Assistec can help you organise the maintenance of your CNC machine tool

At Assistec, we offer electrical or mechanical servicing for machine tools, including repairs for axis drives, spindles and motors, as well as the sale of spare parts (fuses, batteries and electrical equipment for cabinets). For over 25 years, we have been searching for and finding the best solutions to provide a comprehensive all-round service capable of optimising any company's machine fleet, also for multiple brands such as Fanuc, Mitsubishi and more). Moreover, driven by a perpetual quest for improvement, we have recently inaugurated a new department dedicated entirely to the integration of CNC machine tools and robots.

Avoid downtime and anticipate production risks by scheduling a maintenance or CNC monitoring appointment. Contact us or call +39 0522989436 for more information. One of our operators will get back to you with a personalised offer.

Recent Posts

-

MAPPS Mori Seiki: cutting-edge technology at the service of CNC programming

In the world of CNC machining, Mori Seiki has always been synonymous with precision, efficiency and innovation. Among the systems that have contributed most to building this reputation, MAPPS (Machine Advanced Programming Production System) occupies a place of absolute importance. This hardware, integrated into Mori Seiki machines (updated in CELOS), allows for intelligent management of every stage of production, from programming to simulation. Today, thanks to the many years of experience of the Assistec laboratory, it is possible to repair MAPPS Mori Seiki, with the certainty of turning to a team of qualified, up-to-date and responsive professionals.

-

CNC lathes are the beating heart of many mechanical workshops and manufacturing companies. However, their ability to guarantee precision, production continuity and impeccable finishes depends on a factor that is often underestimated: maintenance. Regular mechanical and electronic maintenance is not only a technical requirement, but also a business strategy that reduces machine downtime, preserves product quality and extends the life of the equipment. This guide explores all the operations necessary for comprehensive maintenance, with practical advice and guidance on when it is essential to rely on specialised professionals.

-

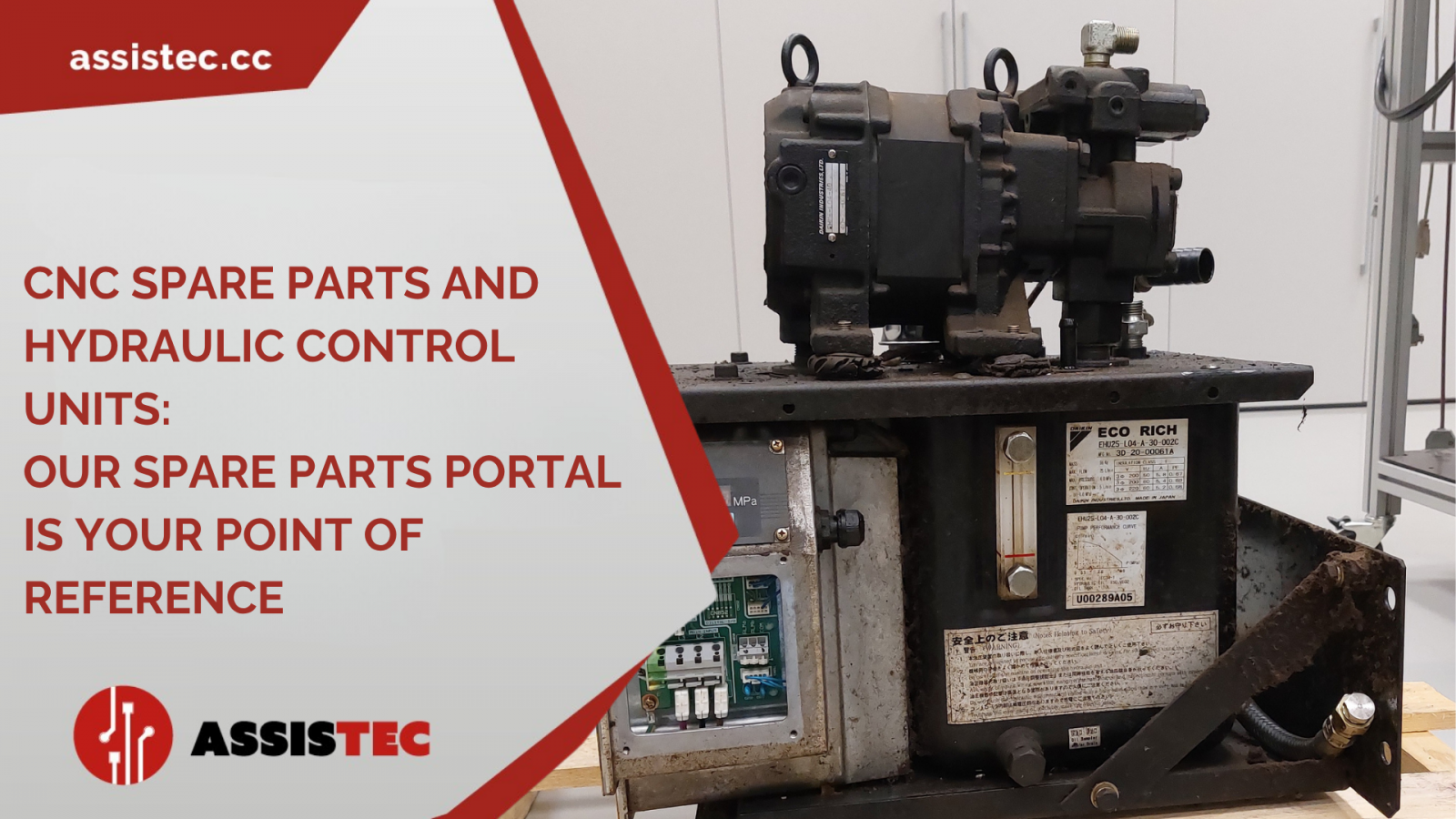

The efficient management of CNC machine tools cannot be separated from a reliable, timely and well-organised spare parts system. This is where the Assistec Spare Parts Portal comes into play, designed to provide concrete support to workshops, maintenance technicians, technical managers and industrial buyers.

Thanks to direct integration with the automated warehouse, the portal allows you to identify and order new and remanufactured components in just a few clicks, with real availability and fast shipping.

Among the most requested spare parts today are hydraulic control units, which are essential for ensuring the operational continuity of CNC systems