Mecspe 2025 - Assistec

MECSPE 2025 is one of Europe's leading trade fairs dedicated to innovation in the manufacturing industry. It is a crucial event for companies that want to stay up-to-date with the latest technologies, solutions and trends in the industry.

Over the years, MECSPE has helped transform artisanal processes into large-scale precision industrial systems. Today, the show serves as a meeting point for machinery manufacturers, technology suppliers, system integrators, and end users, creating an ideal environment for networking and knowledge exchange.

MECSPE is essential to discover how to automate and digitise production processes, improve efficiency, reduce costs and increase competitiveness. In this context, Assistec has decided to play a leading role once again, confirming its presence also in the 2025 edition.

Why visit MECSPE 2025?

Why not miss MECSPE 2025? Imagine plunging into the beating heart of manufacturing innovation, in BolognaFiere from 5th to 7th March. MECSPE is not just a trade show, but a journey to discover the trends that are redesigning the future of industry.

Here's why you should definitely attend:

• Meet Industry Leaders: You will have the unique opportunity to get in direct contact with the companies that are driving innovation, previewing their cutting-edge products and solutions.

• Network: MECSPE is the ideal place to make new strategic connections and strengthen relationships with your current partners.

• Stay up-to-date: Thanks to the numerous educational events, you can deepen your knowledge on the latest technologies and industry trends.

• Explore a complete industry panorama: The 13 themed exhibitions will give you a 360-degree view of the most innovative materials, products and technologies for every manufacturing sector.

• Find the inspiration you are looking for: Be surprised by the creative solutions and innovative ideas MECSPE has to offer, you might find just what your company needs to take the leap forward.

With more than 66,000 visitors and more than 2,000 companies attending the 2024 edition, MECSPE is the reference event for those who want to keep up with the times and seize the opportunities offered by the industrial transformation.

What to expect at MECSPE 2025

The 2025 edition will focus on topics such as industrial automation, digitisation, Industry 4.0, sustainability, new manufacturing technologies (additive manufacturing, collaborative robotics, artificial intelligence) and innovative materials.

Visitors will be able to explore exhibition areas dedicated to machine tools, robotics, automation, quality control, industrial software, additive manufacturing, treatments and finishes, logistics, electronics, subcontracting and services for industry.

MECSPE 2025 will offer a rich programme of side events, including workshops, conferences, round tables and practical demonstrations, allowing attendees to deepen their knowledge and exchange views with industry experts. There will be areas dedicated to success stories and company testimonials.

The fair will be an excellent opportunity to create new partnerships, meet potential business partners, suppliers and customers, and expand your professional network.

Assistec at MECSPE 2025

Assistec will be present at MECSPE 2025 on two stands:

•stand Renishaw stand (Hall 19 - Stand D46)

•stand Riki Macchine Utensili stand (Hall 16 - Stand E04)

The event will be held from 5th to 7th March 2025 and will be an opportunity for all visitors to meet Assistec technicians and discover the latest innovations, including those related to the ROBO FEED world.

An example? The new ROBO FEED CX, an innovative machine with cobots and a flexible component feeding system: a preview not to be missed!

It doesn't end here: Assistec's services are perfectly integrated with the themes of MECSPE, providing concrete solutions to optimise the performance of machine tools, reduce downtime, improve the efficiency of production processes and support companies on the path towards Industry 4.0.

Services promoted at the fair:

•CNC Electronics Service: servicing of machine tools with Fanuc, Mitsubishi and other manufacturers' electronics. Repair of drives, motors, electronic boards and other components. Preventive telephone diagnosis and rapid intervention to minimise machine downtime.

•CNC Mechanical Service: Routine and extraordinary maintenance on multi-brand machine tools. Overhaul of spindles and electro-spindles.Replacement of guides and slides, grinding of spindle cones, maintenance and replacement of refrigerators (chillers).

•Retrofit and Revamping: Upgrading and improving the functionality of obsolete machine tools by replacing electronic and mechanical components. Implementation of new automation and control systems.Adaptation to current safety regulations.

•Industrial automation: Integration of robots for workpiece loading/unloading, push bar systems, gantry loaders and other automated solutions for CNC machine tools. RoboFeed systems for handling non-stackable or small to medium-sized workpieces.

•Predictive Maintenance: Customised service contracts to schedule downtime and plan maintenance work, extending machine life and reducing repair costs.

• Spare Parts Sales: Large stock of spare parts for CNC machine tools, with Just in Time shipping service to minimise downtime. Spare parts for brands such as Fanuc and Mitsubishi.

•Industry 4.0: Solutions for interconnecting CNC machines to third-party MES or ERP systems, real-time production monitoring, data analysis and business performance improvement. Integration with Fanuc MT-LINKi and NCGuide software.

Visit our stand at MECSPE 2025 and be inspired by our innovative solutions for the manufacturing industry of the future.

Our engineers are at your disposal to discuss your company's specific needs.

Conclusion

MECSPE 2025 promises to be the must-attend event for the manufacturing industry, a unique opportunity to immerse oneself in the latest innovations and discover the technologies that will transform the future of manufacturing.

In this rapidly changing scenario, the ability to adapt and optimise processes is key to maintaining a competitive advantage.

Assistec is the ideal strategic partner for companies that want to meet the challenges of the market with concrete, cutting-edge solutions. Don't miss the opportunity to visit our stand, where you can get hands-on experience and expertise in technical support, repair and automation of CNC machine tools.

Whether you are looking to reduce machine downtime, improve machining accuracy, optimise maintenance costs or integrate Industry 4.0 solutions, the Assistec team is ready to listen to your needs and offer personalised support

Join us at MECSPE 2025: we will help you turn your challenges into opportunities, guiding you towards a future of success and sustainable growth.

Contact us today to schedule an appointment with our experts during the show and discover how Assistec can make a difference for your company.

Together, we can build a future of excellence for your company.

Recent Posts

-

MAPPS Mori Seiki: cutting-edge technology at the service of CNC programming

In the world of CNC machining, Mori Seiki has always been synonymous with precision, efficiency and innovation. Among the systems that have contributed most to building this reputation, MAPPS (Machine Advanced Programming Production System) occupies a place of absolute importance. This hardware, integrated into Mori Seiki machines (updated in CELOS), allows for intelligent management of every stage of production, from programming to simulation. Today, thanks to the many years of experience of the Assistec laboratory, it is possible to repair MAPPS Mori Seiki, with the certainty of turning to a team of qualified, up-to-date and responsive professionals.

-

CNC lathes are the beating heart of many mechanical workshops and manufacturing companies. However, their ability to guarantee precision, production continuity and impeccable finishes depends on a factor that is often underestimated: maintenance. Regular mechanical and electronic maintenance is not only a technical requirement, but also a business strategy that reduces machine downtime, preserves product quality and extends the life of the equipment. This guide explores all the operations necessary for comprehensive maintenance, with practical advice and guidance on when it is essential to rely on specialised professionals.

-

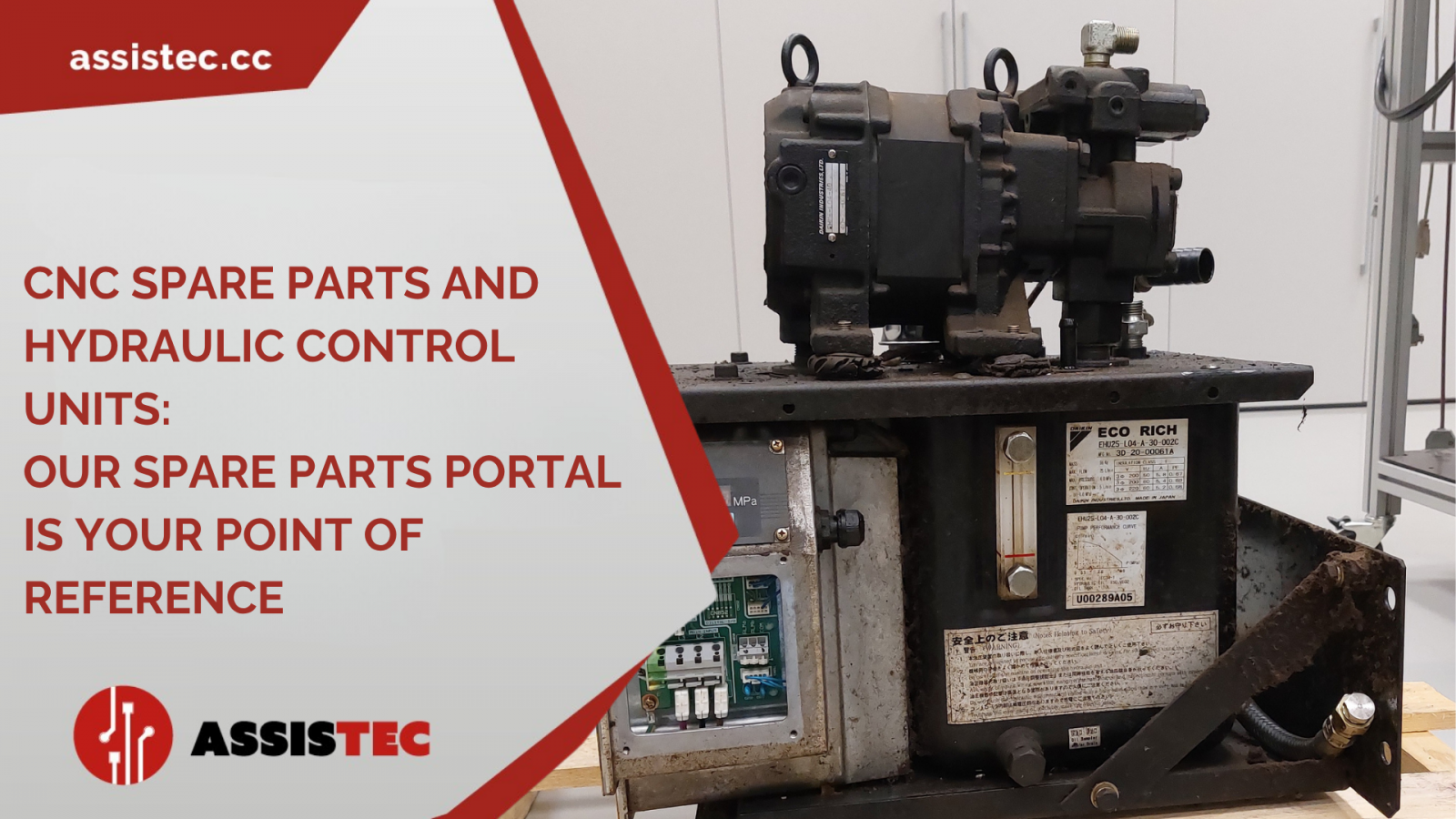

The efficient management of CNC machine tools cannot be separated from a reliable, timely and well-organised spare parts system. This is where the Assistec Spare Parts Portal comes into play, designed to provide concrete support to workshops, maintenance technicians, technical managers and industrial buyers.

Thanks to direct integration with the automated warehouse, the portal allows you to identify and order new and remanufactured components in just a few clicks, with real availability and fast shipping.

Among the most requested spare parts today are hydraulic control units, which are essential for ensuring the operational continuity of CNC systems