Services and products to support machine tools

A dynamic company that offers technical, electronic and mechanical support for machine tools, as well as spare parts, repairs and robotic automation systems. Massimo Mora, Sales Manager of Assistec, tells us about it.

Technical assistance and robotic cells

Assistec was founded more than 20 years ago by Antonio La Placa to provide mechanical workshops with the electronic and technical assistance that was becoming increasingly necessary due to the widespread use of CNC machine tools. From the beginning, the company stood out for its internal electronic repair workshop that was set up to support the servicing activity, but also to provide direct assistance to customers. The second generation at Assistec has expanded the services offered by introducing mechanical assistance that relies on the new internal workshop. The latest addition is the robotics division, which has created a family of robotic cells ready to be integrated into the various production facilities and which is working constantly on the design and construction of islands according to customer specifications.

How is your business structured and characterised?

Assistec is divided into four business units. Our core business is electronic and mechanical assistance for machine tools, which is carried out by specialised technicians at the customer's premises. We also specialise in the integration and interconnection of machines to company management systems. The assistance service is supported by the sale of spare parts for machine tools, which is also made available to all customers. The main brands we deal with are Fanuc and Mitsubishi, along with many others. Repairs are carried out both in our electronic workshop and mechanical workshop, which perform complete overhauls of machine tools or individual components. The latest arrival, but just as important, is the area dedicated to the design and installation of robotic islands for servicing CNC machine tools.

What are the company's strengths?

One of our main strengths is the know-how and expertise of our electronic and mechanical technicians, gained through years of experience and continuous training. A remote diagnostics system allows us to go to the customer's premises with the necessary spare parts and to resolve the fault on the first visit, thus significantly reducing downtime. The efficiency and speed of repairs in our workshop is also very important. Furthermore, our in-depth knowledge of CNC machine tools and machining processes has enabled us to develop robotic automation systems according to the special requirements of our customers in terms of workpiece handling and production flexibility.

What are the cornerstones of your operating philosophy?

We find the best solutions by offering our knowledge, skills and experience. Our constant growth is the result of the trust that hundreds of companies have placed in us for more than 20 years. In addition, we have a deep relationship of friendship and cooperation with our technological partners, who are indispensable for the development of our projects and the achievement of increasingly ambitious goals.

What does the concept of quality mean to you?

For us, quality means three things: competence, timeliness and guarantee. Competence comes from the experience and constant updating of our technicians, timeliness is the goal that we achieve every day in fixing faults with our diagnostic tools and interventions, and the guarantee of success is the result of the high level of our repairs and the real-life tests we carry out on all our spare parts.

What are the main demands of your customers?

Today, most customers implement a “just in time” system. Job orders have very short lead and production times, and production runs are much smaller. Machine downtime can cause huge problems, resulting in delays and financial losses. Therefore, our daily activity allows customers to resume production immediately, without any interruptions.

What kind of robotic automated systems do you have?

The line of Robofeed machines features standard plug & play robotic islands, compact, without the need for safety gates and with a wide range of customisation options.

• Robofeed series A: for loading/unloading and manipulation in the various machining phases of small to medium, non-stackable parts;

• Robofeed series S: pallet recirculating stockers dedicated to the servicing of CNC machines for stackable parts of various sizes;

• Robofeed series C: collaborative robotic system for perfect human-machine interaction.

The Robofeed Custom systems are designed and installed to customer specifications, with prior analysis of the real needs for system capacity and production flexibility.

How are you organised in terms of spare parts and stock?

The sale of spare parts supports the electronic and mechanical assistance service. The main brands we carry are Fanuc, Mitsubishi, Siemens and Daikin, as well as others. In addition to new spare parts, we are also able to supply compatible spare parts or modules reconditioned by our internal electronic workshop. All spare parts can be purchased from our new e-shop www.centroriparazionicnc.it

How do you help make your customers more competitive?

Since 2012, we have been pursuing the objective of offering customers a comprehensive machine tool assistance service; we are a unique partner in electronic and mechanical maintenance, offering total care. Our internal workshops allow us to offer spare parts and repairs at competitive prices, and the introduction of the robotic division has significantly expanded our range of services and products. All this delivers benefits to our customers.

How do you organise staff training?

Assistec supports employees and the business with training courses carried out internally and at leading training centres, or directly at the companies that manufacture the CNC machines and robots. Every year we organise team building days designed to strengthen the bond between workers, and to ensure that the company’s mission is always shared with the whole team.

How have you gained the trust of your customers?

Anyone who decides to make service its core business, knows that they must strive to leave a lasting and positive mark on the customer. Assistance only bears fruit when a relationship of trust is established and maintained over time. The sale of a spare part may seem to be an end in itself, but when it is integrated into a fault analysis and repair service, it becomes a whole. We want to protect our customers as much as possible from unexpected technical problems by providing a free daily helpline service.

Finally, what is the future of your company?

Digitalisation will play an increasingly important role for Assistec, through the implementation of a system that will allow us to make a quantum leap in customer support. This year, we are also strengthening our offer in the field of robotics.

Recent Posts

-

MAPPS Mori Seiki: cutting-edge technology at the service of CNC programming

In the world of CNC machining, Mori Seiki has always been synonymous with precision, efficiency and innovation. Among the systems that have contributed most to building this reputation, MAPPS (Machine Advanced Programming Production System) occupies a place of absolute importance. This hardware, integrated into Mori Seiki machines (updated in CELOS), allows for intelligent management of every stage of production, from programming to simulation. Today, thanks to the many years of experience of the Assistec laboratory, it is possible to repair MAPPS Mori Seiki, with the certainty of turning to a team of qualified, up-to-date and responsive professionals.

-

CNC lathes are the beating heart of many mechanical workshops and manufacturing companies. However, their ability to guarantee precision, production continuity and impeccable finishes depends on a factor that is often underestimated: maintenance. Regular mechanical and electronic maintenance is not only a technical requirement, but also a business strategy that reduces machine downtime, preserves product quality and extends the life of the equipment. This guide explores all the operations necessary for comprehensive maintenance, with practical advice and guidance on when it is essential to rely on specialised professionals.

-

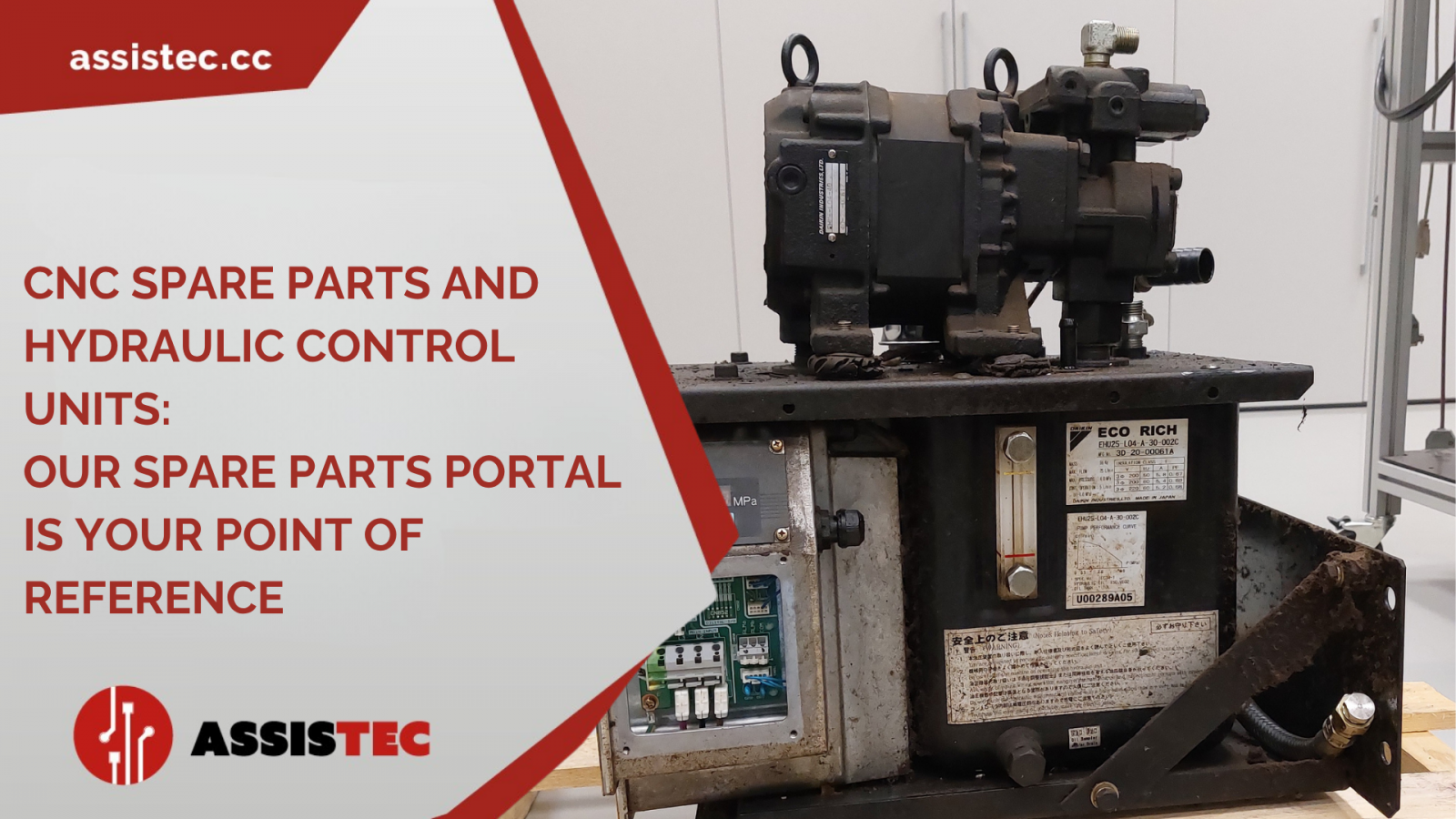

The efficient management of CNC machine tools cannot be separated from a reliable, timely and well-organised spare parts system. This is where the Assistec Spare Parts Portal comes into play, designed to provide concrete support to workshops, maintenance technicians, technical managers and industrial buyers.

Thanks to direct integration with the automated warehouse, the portal allows you to identify and order new and remanufactured components in just a few clicks, with real availability and fast shipping.

Among the most requested spare parts today are hydraulic control units, which are essential for ensuring the operational continuity of CNC systems